Knowledge Article from www.Key-to-Steel.comCast irons are alloys of iron, carbon, and silicon in which more carbon is present than can be retained in solid solution in austenite at the eutectic temperature. In gray cast iron, the carbon that exceeds the solubility in austenite precipitates as flake graphite.

Gray irons usually contain 2.5 to 4% C, 1 to 3% Si, and additions of manganese, depending on the desired microstructure (as low as 0.1% Mn in ferritic gray irons and as high as 1.2% in pearlitics). Sulphur and phosphorus are also present in small amounts as residual impurities.

The composition of gray iron must be selected in such a way to satisfy three basic structural requirements:

1. The required graphite shape and distribution

2. The carbide-free (chill-free) structure

3. The required matrix

For common cast iron, the main elements of the chemical composition are carbon and silicon. High carbon content increases the amount of graphite or Fe3C. High carbon and silicon contents increase the graphitization potential of the iron as well as its castability. The combined influence of carbon and silicon on the structure is usually taken into account by the carbon equivalent (CE):

CE = %C + 0.3x(%Si) + 0.33x(%P) - 0.027x(%Mn) + 0.4x(%S)

Although increasing the carbon and silicon contents improves the graphitization potential and therefore decreases the chilling tendency, the strength is adversely affected. This is due to ferrite promotion and the coarsening of pearlite.

The manganese content varies as a function of the desired matrix. Typically, it can be as low as 0.1% for ferritic irons and as high as 1.2% for pearlitic irons, because

manganese is a strong pearlite promoter.

The effect of sulfur must be balanced by the effect of manganese. Without manganese in the iron, undesired iron sulfide (FeS) will form at grain boundaries. If the sulfur content is balanced by manganese, manganese sulfide (MnS) will form, which is harmless because it is distributed within the grains. The optimum ratio between manganese and sulfur for a FeS-free structure and maximum amount of ferrite is:

%Mn = 1.7x(%S) + 0.15Other minor elements, such as aluminum, antimony, arsenic, bismuth, lead, magnesium, cerium, and calcium, can significantly alter both the graphite morphology and the microstructure of the matrix.

In general, alloying elements can be classified into three categories.

1.

Silicon and aluminum increase the graphitization potential for both the eutectic and eutectoid t

transformations and increase the number of graphite particles. They form colloid solutions in the matrix.

Because they increase the ferrite/pearlite ratio, they lower strength and hardness.

2. Nickel, copper, and tin increase the graphitization potential during the eutectic transformation, but

decrease it during the eutectoid transformation, thus raising the pearlite/ferrite ratio. This second effect is

due to the retardation of carbon diffusion. These elements form solid solution in the matrix. Since they

increase the amount of pearlite, they raise strength and hardness.

3. Chromium, molybdenum, tungsten, and vanadium decrease the graphitization potential at both

stages. Thus, they increase the amount of carbides and pearlite. They concentrate in principal in the

carbides, forming (FeX)nC-type carbides, but also alloy the aFe solid solution. As long as carbide formation

does not occur, these elements increase strength and hardness. Above a certain level, any of these elements

will determine the solidification of a structure with Fe3C (mottled structure), which will have lower

strength but higher hardness.

Generally, it can be assumed that the following properties of gray cast irons increase with increasing tensile strength from class 20 to class 60:

* All strengths, including strength at elevated temperature

* Ability to be machined to a fine finish

* Modulus of elasticity

* Wear resistance.

On the other hand, the following properties decrease with increasing tensile strength, so that low-strength irons often perform better than high-strength irons when these properties are important:

* Machinability

* Resistance to thermal shock

* Damping capacity

* Ability to be cast in thin sections. Successful production of a gray iron casting depends on the fluidity of the

molten metal and on the cooling rate, which is influenced by the minimum section thickness and on section

thickness variations.

Casting design is often described in terms of section sensitivity. This is an attempt to correlate properties in critical sections of the casting with the combined effects of composition and cooling rate. All these factors are interrelated and may be condensed into a single term, castability, which for gray iron may be defined as the minimum section thickness that can be produced in a mold, cavity with given volume/area ratio and mechanical properties consistent with the type of iron being poured.

Scrap losses resulting from missruns, cold shuts, and round corners are often attributed to the lack of fluidity of the metal being poured.

Mold conditions, pouring rate, and other process variables being equal, the fluidity of commercial gray irons depends primarily on the amount of superheat above the freezing temperature (liquidus). As the total carbon content decreases, the liquidus temperature increases, and the fluidity at a given pouring temperature therefore decreases. Fluidity is commonly measured as the length of flow into a spiral-type fluidity test mold.

The significance of the relationships between fluidity, carbon content, and pouring temperature becomes apparent when it is realized that the gradation in strength in the ASTM classification of gray iron is due in large part to differences in carbon content

(~3.60 to 3.80% for class 20; ~2.70 to 2.95% for class 60). The fluidity of these irons thus resolves into a measure of the practical limits of maximum pouring temperature as opposed to the liquidus of the iron being poured.

The usual microstructure of gray iron is a matrix of pearlite with graphite flakes dispersed throughout. Foundry practice can be varied so that nucleation and growth of graphite flakes occur in a pattern that enhances the desired properties. The amount, size, and distribution of graphite are important. Cooling that is too rapid may produce so-called chilled iron, in which the excess carbon is found in the form of massive carbides. Cooling at intermediate rates can produce mottled iron, in which carbon is present in the form of both primary cementite (iron carbide) and graphite.

Flake graphite is one of seven types (shapes or forms) of graphite established in ASTM A 247. Flake graphite is subdivided into five types (patterns), which are designated by the letters A through E. Graphite size is established by comparison with an ASTM size chart, which shows the typical appearances of flakes of eight different sizes at l00x magnification.

Type A flake graphite (random orientation) is preferred for most applications. In the intermediate flake sizes, type A flake graphite is superior to other types in certain wear applications such as the cylinders of internal combustion engines.

Type B flake graphite (rosette pattern) is typical of fairly rapid cooling, such as is common with moderately thin sections (about 10 mm) and along the surfaces of thicker sections, and sometimes results from poor inoculation.

The large flakes of type C flake graphite are formed in hypereutectic irons. These large flakes enhance resistance to thermal shock by increasing thermal conductivity and decreasing elastic modulus. On the other hand, large flakes are not conducive to good surface finishes on machined parts or to high strength or good impact resistance.

The small, randomly oriented interdendritic flakes in

type D flake graphite promote a fine machined finish by minimizing surface pitting, but it is difficult to obtain a pearlitic matrix with this type of graphite. Type D flake graphite may be formed near rapidly cooled surfaces or in thin sections. Frequently, such graphite is surrounded by a ferrite matrix, resulting m soft spots in the casting.

Type E flake graphite is an interdendritic form, which has a preferred rather than a random orientation. Unlike type D graphite, type E graphite can be associated with a pearlitic matrix and thus can produce a casting whose wear properties are as good as those of a casting containing only type A graphite in a pearluic matrix. There are, of course, many applications in which flake type has no significance as long as the mechanical property requirements are met.

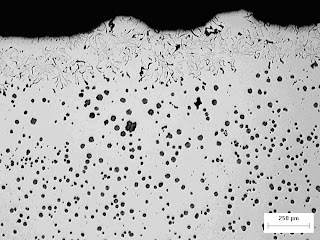

Figure 7: Sample with chunky graphite present due to excess concentration of rare earth metals.

Figure 7: Sample with chunky graphite present due to excess concentration of rare earth metals.